Discover the ICON Parachute System From BRS (Ballistic Recovery Systems)

From day one, ICON’s mission has been to introduce as many current and aspiring pilots to aviation as possible. Enabling explorers of all experience levels to unlock a new sense of adventure is the ICON A5’s calling card. For some owners, this means earning their pilot’s license and fulfilling that long-held aspiration of becoming a private pilot. For others who already have their certificate, their adventure might entail unlocking a new environment that they’ve never experienced before. Regardless, designing the next generation A5 meant that ICON needed to plan for the unexpected. And as a result, ICON’s product development team spent years designing layer upon layer of safety into the amphibious ICON A5.

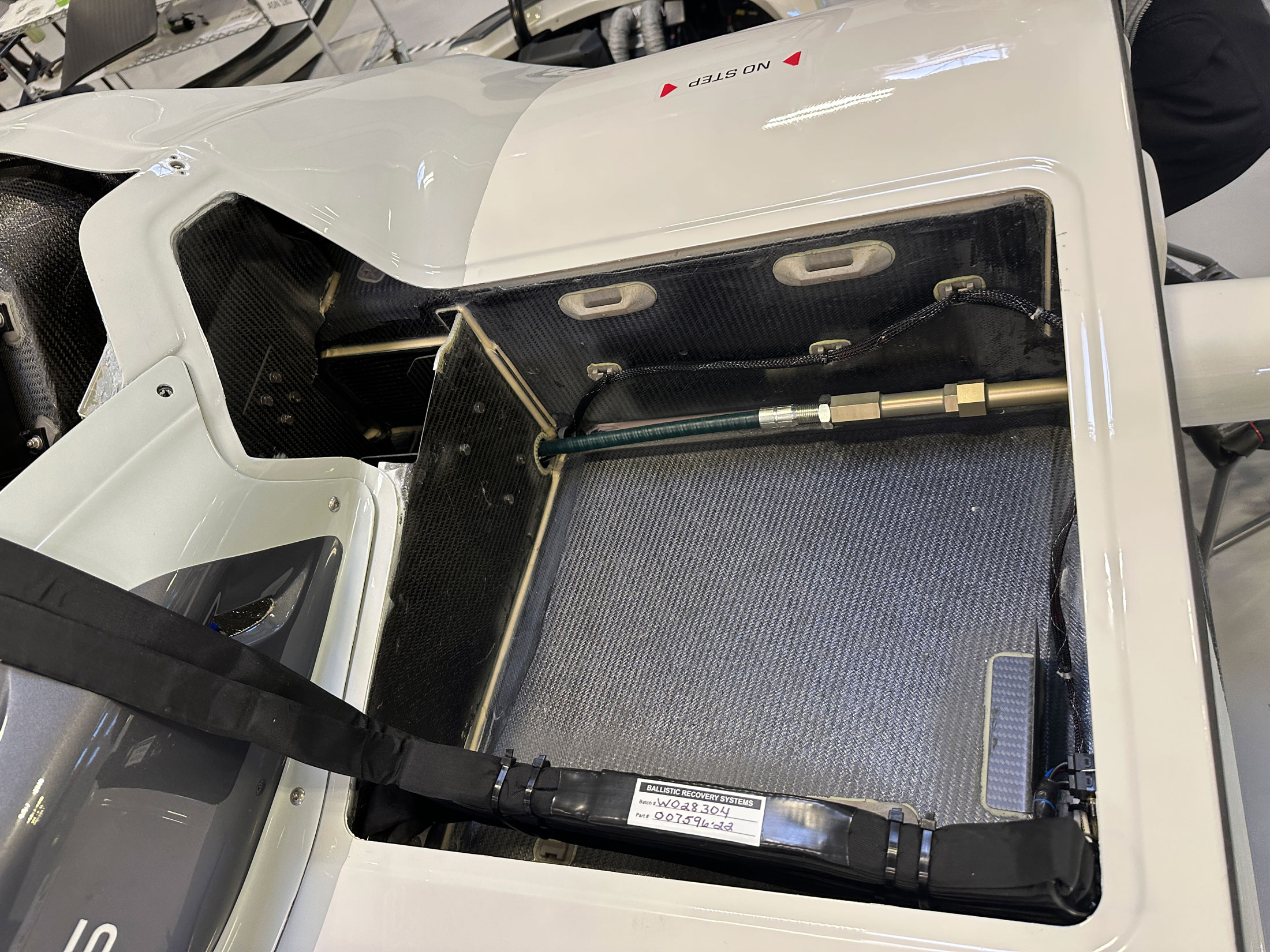

The Angle of Attack Indicator (AoA) and the spin-resistant airframe are two of the primary features designed to aid the pilot in the cockpit. But ICON also made a conscious decision to make the ICON Parachute System, developed by BRS Aerospace, standard in each and every ICON A5. Combining this system with the AoA, spin-resistant airframe, and incredible versatility creates an unparalleled sense of security in the A5 cockpit. For more information on the A5’s features mentioned above, please explore the ICON A5 safety page here. In regards to the ICON Parachute System, here is a bit more information as to how it is integrated with the A5 and the history of the manufacturer.

BRS Aerospace

While innovative and relatively new to general aviation, rudimentary parachute systems have existed almost as long as airplanes themselves. It wasn’t until the need for such a safety system became apparent in the early years of hang gliding that we see the rapid innovation and implementation of parachute systems for light sport and recreational aircraft.

The more modern rescue systems, such as the ICON Parachute System, have been in existence for nearly a half-century, with BRS Aerospace being one of the leading manufacturers. BRS founder, Boris Popov, survived a hang glider accident when he lost control of his aircraft in flight. Not wanting to abandon his sport, or fall victim to the same event twice, he invented a parachute that could dramatically increase survival in the case of a catastrophic event. This initial parachute evolved into ballistic, or rocket propelled systems. The ballistic version certainly deployed quicker but caused a number of issues in respects to hang gliders. A broken hang glider would sometimes engulf the pilot and trap the rocket from deploying. Propellants were also of lower quality and sometimes did not fire when needed.

While ballistic systems didn’t take off as quickly for hang gliders, it did for aircraft controlled from a cockpit as opposed to a crossbar. From the 90s into the 2000s, BRS and other manufacturers continued to hone ballistic parachute technology to where we are today. Decades of research and development, from hang gliders to fixed wing planes, have led to a reliable rescue system.

How does the system deploy on the ICON A5

The parachute has three attachment points on the ICON A5 — two on the spar and one located close to the egress area. When the ICON Parachute System is activated from the cockpit, the rocket will fire, it will expose and break away the parachute egress, and then fully deploy the parachute. Once it starts unfolding, and moments after the lines become taught, the aircraft will become stabilized at a controlled, nose-down angle. This angle is intentional, mostly so the pilot’s and passenger’s feet can brace and take more of the impact, as opposed to landing parallel to the ground on essentially the seat of your pants. In this regard, an additional, unique feature to the ICON Parachute System is a switch that identifies when the rocket has been deployed. This switch will lower the landing gear or ensure it is down for an additional shock absorber.

How does ICON verify the parachute’s quality?

As mentioned above, BRS is going on decades of experience and testing. When we receive the system and implement it into the aircraft, our team ensures the proper placement and the structural integrity of the attachment points to the A5. Everything from the metal tangs connecting the ICON Parachute to the airframe and the webbing on the parachute itself is the design of BRS.

This being said, the ICON engineering team chose a parachute system that is designed for aircraft much larger than the A5. Given untested variables that could be presented in the case of the parachute’s usage, we wanted to make sure that the ICON Parachute System would support the aircraft through many different scenarios. The physics are simple: the larger the parachute, the slower the descent rate.

ICON has performed extensive stress analysis with at least 150% safety margin for each component of the parachute’s attachment points to the aircraft. We’ve also physically developed the deployment sequence of the aircraft to ensure it will deploy properly. This ensures the parachute is going to take any additional forces that were not originally intended. The ICON Parachute System, by design, can handle not only the static weight of the aircraft, but the dynamic loading of a fast moving or out of control aircraft.

When should the ICON A5 parachute system be deployed?

The ICON Parachute System was designed for usage during catastrophic events. The term “catastrophic” in aviation is usually not subjective. It entails an inability to control the aircraft — primary flight controls have been compromised or the powerplant has lost the ability to generate meaningful thrust with no safe place to land in gliding distance. In the latter scenario, the pilot has few, if any, possible landing areas to put the aircraft down safely, thus deploying the parachute will slow the aircraft’s descent rate, adjust the attitude of aircraft upon impact, and greatly improve the survival rate for the pilot and passenger on board. Given the versatility of the aircraft, it is advised to find a water environment if practicable. Otherwise, there should be no hesitation to utilize the ICON Parachute System.

What pilots should take away

While ICON is proud to make the ICON Parachute System a standard feature in every A5, there has not been a reported case where pilots have activated the parachute system. This doesn’t mean it shouldn’t be or it never will. But it is a testament to the state-of-the-art safety features of the ICON A5, the reliable Rotax 912iS powerplant, and the redundancy of an amphibious aircraft. In the event a pilot should need to pull the parachute, they will be utilizing a system over-built for the ICON A5. We recognize that the margin of error for a human life is very small, so we over-engineered the ICON A5 by a large margin. The ICON Parachute System reflects ICON’s mission to introduce aviation to as many people as possible. For someone enticed by the adventures aviation presents, but intimidated by exploring a new sport or hobby, the parachute offers a unique sense of safety by accounting for catastrophic events.

For those interested in learning more about the ICON A5 or interested in experiencing the aircraft firsthand, please contact us here.